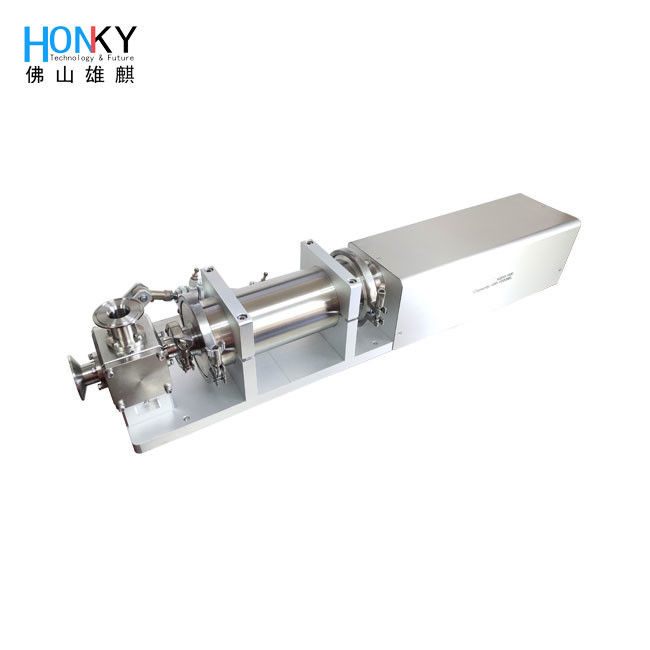

Bomba de pistones cerámicos industriales de alta precisión, duradera para líneas de producción a gran escala

Servo accionado de alta precisión cerámica bomba de pistón con ajuste automático de volumen para el relleno de crema de pasta de mermelada

Parámetro de una bomba de pistón cerámica industrial de alta precisión

| Modelo |

Se trata de una serie de datos. |

Se trata de una serie de datos. |

Se trata de una serie de datos. |

Se aplicará el procedimiento siguiente: |

| Cabeza de la bomba |

Cerámica de alta pureza |

| Precisión de llenado |

¥ ± 0,5% |

| Rango de llenado |

1 a 12 ml |

2 a 25 ml |

5 a 50 ml |

10 a 100 ml |

| Velocidad de fabricación |

0 a 50 botellas/min |

| Tamaño de la bomba |

50*15*15 cm |

| El poder |

AC 220V 50-60Hz 50W |

| Presión del aire |

0.4-0.6Mpa |

| Tipo de motor |

Motor paso a paso/servomotor |

El conjunto de la bomba neumática de émbolo cerámico adopta un diseño de émbolo cerámico de precisión, que es adecuado para la infusión cuantitativa de líquidos de viscosidad media y alta, cremas,y cremas (1000-100,000CPS) y materiales que contienen ciertas partículas.

Características de una bomba de pistón cerámica industrial de alta precisión

La bomba de llenado de pistón de cerámica de grado alimenticio es una solución de precisión para la industria de alimentos y bebidas.y confiabilidad, ideal para formulaciones sensibles y de alto valor.

1Diseñado con precisión para la excelencia en alimentos y bebidas.

Su mecanismo rotativo a lineal utiliza un pistón de cerámica en una manga de grado alimenticio; la longitud de la carrera se ajusta mediante el ángulo de la cabeza de la bomba.eliminación de la pulsación y la inconsistencia de las bombas convencionales.

Manejo suave

La rotación suave permite un flujo constante y sin aireación, preservando la calidad de la miel, las emulsiones y la pulpa de la fruta.

Precisión superior

La precisión de ±0,5% y la repetibilidad de ±0,1% reducen el desperdicio del producto, reduciendo los costes de los ingredientes de alto valor.

2Construido para la higiene, seguridad y durabilidad.

Hecho de materiales compatibles con los alimentos, es fácil de limpiar y duradero para ambientes de producción de alimentos duros.

Pistones de cerámica

Resistente al desgaste, inerte y ultra suave, resiste pegarse y simplifica la limpieza, incluso para miel o chocolate.

Partes de calidad alimentaria

El acero inoxidable 316L y los componentes mojados con PEEK/PTFE ofrecen resistencia a la corrosión para alimentos ácidos/salinos.

3- Integración perfecta en las líneas de producción

Esta bomba actúa como un sistema de llenado completo listo para integrarse, no sólo como un componente.

Control inteligente

Interfaces con PLC / SCADA vía analógico / digital (RS485 / Modbus) para recetas rápidas, registro de datos y sincronización.

Fácil mantenimiento

El desmontaje rápido admite CIP / SIP, minimizando el tiempo de inactividad y cumpliendo con los estándares de higiene.

Presentación del producto de la bomba de pistón de cerámica industrial de alta precisión

Área de aplicación

- Diseño de productos ODM y OEM

- Diseño de la línea de fabricación automática

- Embalaje de productos cosméticos

- Embalaje de productos farmacéuticos y de biorreactores

- Disposición de líquidos de laboratorio

- Disposición de líquidos por batería de litio

- Diseño de la bomba cerámica y de las piezas de la bomba cerámica

- Material de relleno de otras áreas

Pregunta y respuesta

P: ¿Ofrece servicios OEM, soy un distribuidor del extranjero?

R: Sí, podemos ofrecer servicios OEM y soporte técnico. Bienvenido a iniciar su negocio OEM.

P: ¿Qué tal el servicio postventa?

R: La máquina tiene una garantía de 1 año y ofrecemos servicio postventa y soporte técnico de por vida.

P: ¿Cuáles son sus servicios de instalación?

R: Los servicios de instalación están disponibles con todas las compras de máquinas nuevas.que le indicará cómo usar esta máquina bien.

P: ¿Qué información se necesitará para confirmar los modelos de la máquina?

A: ¿Qué quieres decir?

- El estado material

- Rango de llenado

- Velocidad de fabricación

- Requisitos para el proceso de producción

¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!  ¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!