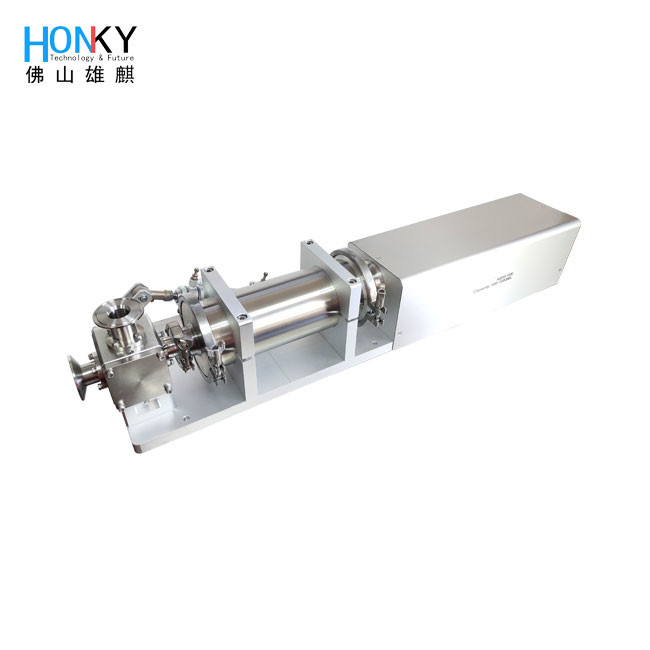

Food-Grade Ceramic Piston Filling Pump – Ideal for Syrups, Honey & Edible Pastes

Servo Driven High Precision Ceramic Piston Pump With Automatic Volume Adjusting For Cream Paste Jam Filling

Parameter of Servo Driven High Precision Ceramic Piston Pump

| Model |

XQQGS-12 |

XQQGS-25 |

XQQGS-50 |

XQQGS-100 |

| Pump head |

High purity ceramics |

| Filling accuracy |

≦±0.5% |

| Filling range |

1-12ml |

2-25ml |

5-50ml |

10-100ml |

| Manufacturing speed |

0-50 Bottle/min |

| Size of the pump |

50*15*15 cm |

| Power |

AC 220V 50-60Hz 50W |

| Air pressure |

0.4-0.6Mpa |

| Motor type |

Step motor/ servo motor |

The ceramic plunger pneumatic pump assembly adopts a precision ceramic plunger design, which is suitable for the quantitative infusion of medium and high viscosity liquids, creams, and creams (1000-100,000CPS) and materials containing certain particles.

Key Features

The Food-Grade Ceramic Piston Filling Pump is an engineered precision solution designed specifically for the demanding requirements of the food and beverage industry. It excels in handling a wide range of viscous, sensitive, and valuable products—from golden syrups and delicate sauces to thick honey and coarse edible pastes—ensuring unparalleled accuracy, hygiene, and reliability.

1. Precision Engineered for Food & Beverage Excellence

At the heart of this pump is a unique rotary-to-linear mechanical system, where a ceramic piston rotates within a food-grade sleeve. The stroke length is precisely adjusted by varying the pump head angle, translating rotation into a highly accurate and repeatable linear displacement. This method eliminates the inconsistency and pulsation common in other pump technologies.

- Gentle Product Handling: The smooth, continuous rotary motion ensures a steady, non-pulsating flow that preserves product integrity and prevents aeration—critical for maintaining the quality of honey, delicate emulsions, and fruit pulps.

- Unmatched Accuracy & Repeatability: Achieve precise fills every time with a metering accuracy better than ± 0.5% and repeatability as high as ± 0.1%. This drastically reduces product giveaway, saving significant costs when filling high-value ingredients.

2. Built for Hygiene, Safety, and Durability

Constructed with fully food-compliant materials, this pump is designed for easy cleaning and long service life in challenging environments.

- Advanced Ceramic Piston: The core of the pump features a highly wear-resistant and chemically inert ceramic piston. It is exceptionally smooth, preventing sticking and ensuring effortless cleaning even with sticky products like honey or chocolate.

- Food-Grade Materials: Wetted parts are available in polished stainless steel (316L) and advanced food-grade polymers (such as PEEK and PTFE), offering excellent corrosion resistance and compatibility with a vast array of food products, including acidic and saline solutions.

3. Seamless Integration into Your Production Line

This pump is more than a component; it's a complete filling system ready for integration.

- Smart Control Ready: Easily interfaces with modern PLCs and SCADA systems via analog signals or digital communication (e.g., RS485/Modbus) for seamless recipe changes, data logging, and production line synchronization.

- Easy to Clean & Maintain: Its design supports quick disassembly for cleaning-in-place (CIP) or sterilizing-in-place (SIP) protocols, minimizing downtime and ensuring the highest standards of hygiene.

Product Display

Application Areas

- ODM and OEM products design

- Automatic manufacturing line design

- Cosmetic product packing

- Pharmaceutical and bio-reagent product packing

- Laboratory Liquid dispensing

- Lithium Battery Liquid dispensing

- Ceramic pump and ceramic pump part design

- Other area's material filling

Frequently Asked Questions

Q: Do you offer OEM services, I am a distributor from overseas?

A: Yes, we can offer both OEM Services and technical support. Welcome to start your OEM business.

Q: How about the after-sales service?

A: The machine is a 1-year warranty. And we offer lifetime after-sale service and technical support.

Q: What are your Installation Services?

A: Installation Services are available with all new machine purchases. We will provide the user manual and videos to support installing, debugging, operation of the machine, which will indicate to you how to use this machine well.

Q: What info will be needed to confirm machine models?

A: 1. The material status.

2. Filling range.

3. Manufacturing speed.

4. Requirements for the production process.

¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!  ¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!