Clean Bench Desktop Reagent Tube Filling and Capping Machine

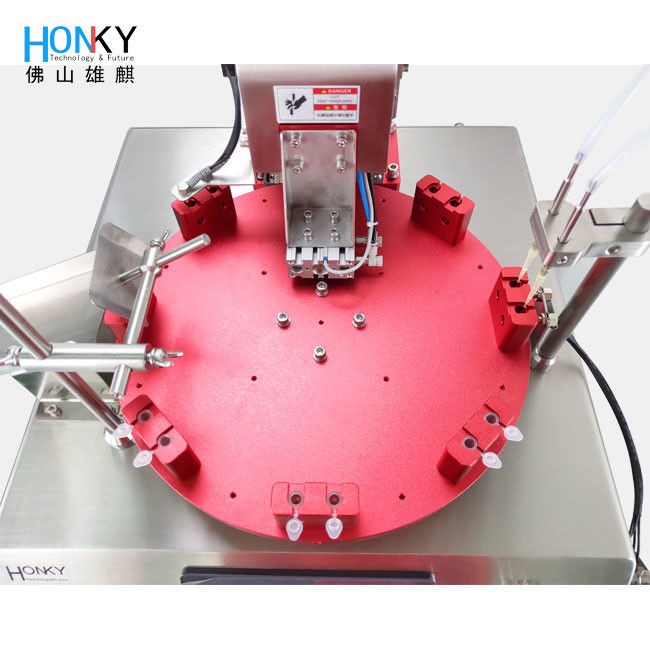

The XQLXG-2S rotary desktop filling machine is a versatile and specialized equipment designed for efficient filling and capping of test tubes. Its innovative rotary design optimizes workflow and ensures continuous processing, making it ideal for laboratories, research facilities, and pharmaceutical manufacturing where precision and speed are essential.

Key Features

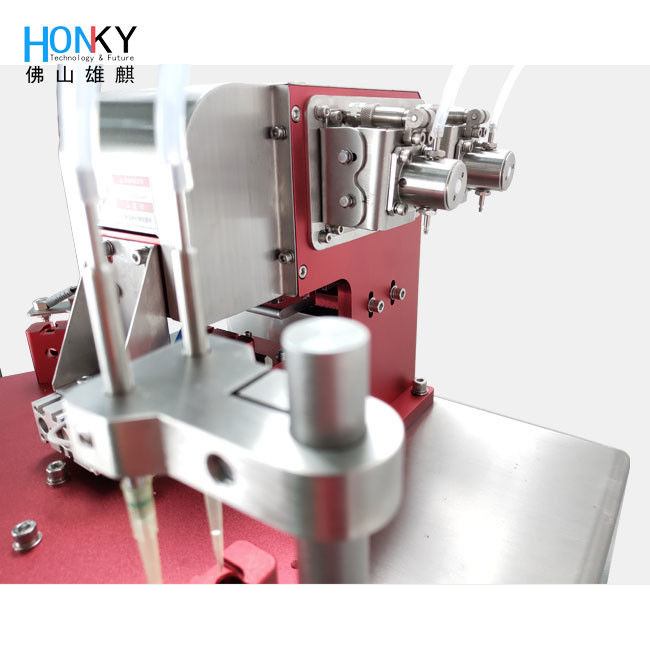

Featuring a self-developed plug pressing structure, this machine simplifies the capping process without complex adjustments or additional tools. The streamlined design ensures simple operation and high efficiency, allowing operators to accurately apply caps with minimal effort.

The XQX2 high-precision ceramic pump guarantees filling accuracy within ±0.5%, ensuring exact liquid amounts in each test tube. With fast filling speeds and wide range capabilities, it accommodates various liquids and volumes for diverse applications.

The integrated bottle-out mechanism streamlines the process by automatically ejecting filled test tubes, enabling single-operator management. This reduces labor costs and enhances workplace safety by minimizing manual handling risks.

Constructed from sanitary stainless steel, the machine features a compact, robust design that withstands daily use while maintaining a clean, hygienic work environment. Smooth surfaces facilitate easy cleaning and disinfection for compliance with healthcare and scientific standards.

Technical Specifications

| Model |

XQLXG-2S |

| Pump Type |

Ceramic Pump |

| Filling Accuracy |

≤±0.5% |

| Filling Range |

0.2-1.5ml |

| Manufacturing Speed |

40 PCS / minute |

| Power |

AC 220V 50-60Hz 550W |

| Air Pressure |

0.4-0.6Mpa |

| Machine Size |

710×660×670mm (Main machine roughly) |

Advanced Characteristics

- Automatic dual-channel bottle loading, filling, capping and discharging

- Constructed from stainless steel 304 for durability and hygiene

- Japanese sensors and Taiwan precision cams for accurate positioning

- Precision ceramic pump with ±0.3% repeat accuracy

- Sensor recognition for no-bottle filling stop function

- Customizable machine size according to customer requirements

Product Display

This equipment has been tested to meet GMP certification requirements.

The separation part uses high purity ceramic pump, controlling injection volume by adjusting pump head angle with exceptional measuring accuracy and repeat consistency.

Fully desktop design for easy operation and space efficiency.

Why Choose HonkyTech?

Rich Experience

Skilled engineering staff with many years of experience in precision-filling industry.

Quality Assurance

Strict quality control system with CE approval and ROHS Certificate.

In Stock

Ready inventory of ceramic pump parts, electronic components, and filling machine spare parts for immediate delivery.

Mature Technology

Numerous in-house service technicians and engineers ready to provide technical support.

Frequently Asked Questions

Q: Do you offer OEM services, I am a distributor from overseas?

A: Yes, we offer both OEM Services and technical support. Welcome to start your OEM business.

Q: How about the after-sales service?

A: The machine includes a 1-year warranty with lifetime after-sale service and technical support.

Q: What are your Installation Services?

A: Installation services are available with all new machine purchases. We provide user manuals and videos for installation, debugging, and operation guidance.

Q: What info will be needed to confirm machine models?

A: 1. The material status

2. Filling range

3. Manufacturing speed

4. Requirements for the production process

¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!  ¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!